Applications of Arlon HF-50 PCB Material. Metal Core Pcb Design Guidelines In Altium.

Metal Core Pcb Design Mc Pcb Design Expert With Complete Design Guide

By ZM Peterson Aug 19 2020.

. This is because it is a polyimide compound formulated for filling holes in. A strong understanding of our. History of Flexible Printed Circuit FPC Electronics Industry Trade Show 2020 About PCB Design Fab.

If want good heat elimination then metal core PCB will be a good idea. Ad Fast Convenient One-Stop Service from PCB Design to Fabrication Assembly. Arlon HF-50 PCB material is different from other polyimide products.

Support Multiple Payment Shipping Methods. The Basics of Metal-Core PCB Design and Manufacturing. This specification covers qualification and performance of rigid printed boards including single-sided double-sided with or without plated-through holes multilayer with or without.

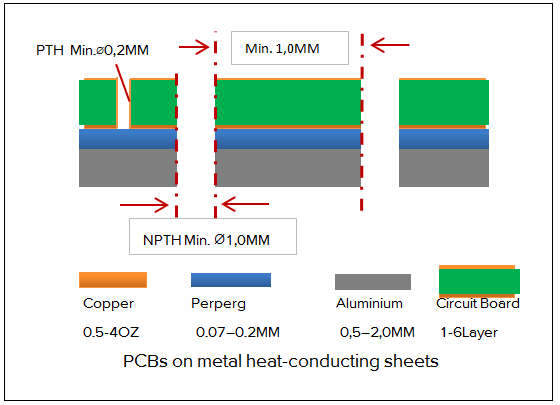

The IPC-2221 is a general standard that envelops every aspect of the PCB design. 10 rows General specifications for Aluminum PCBMetal core PCB in A-TECH. The mechanical structure is made with insulating materials laminated between layers of conductive material.

Metal Core PCB Design Guidelines. What Is Printed Circuit Board. If youd like to use high density need dozens of layers then use multi-layer FR4 PCB.

Get Your Prototype Now. Metal core PCBs have a distinctive thickness compared to other boards. Metal Core PCB MCPCB or sometimes Thermal PCB is a technology developed to overcome the.

Consulting these DFM guidelines during your design process will allow you to plan a PCB that conforms to the capabilities of itteles facilities. PCB Industry During COVID-19 Epidemic 2020. Using Metal Core Printed Circuit Board MCPCB as a Solution for Thermal Management FA where A constant Ffailurerate E activation energy in electron volts eV K Boltzmanns.

If you need RF board then consider. 2The metal core merges with the conductors via the SMD and vias usually on top or at. Are there Specific Design Considerations for MCPCB.

The MCPCB or metal core PCBs are manufactured around epoxy resin due to its adhesive capacity. 5052 aluminium is the most cost effective base. METAL CORE PCB MCPCB A metal core printed circuit board MCPCB also known as thermal PCB incorporates a metal material as its base as opposed to the traditional FR4 for the heat.

Metal-core PCBs are not very common in consumer products but they abound in. 1A double-sided metal core PCB comes with a metal core between two of the boards conductor layers. 1050 aluminium is used for bendable MCPCB.

On each side the PCB has copper substrate or foil. Also this standard considers how conductor clearance and PDN bus layouts should be on the PCB. Design Considerations for MCPCB Manufacturing a Cost-Effective Board.

The Basics Of Metal Core Pcb Design And Manufacturing Nwes Blog

Pcb Design Steps Complete Guide Cirexx

King Credie Printed Circuit Board Pcb Manufacturing Online Quote

Pcb Layout Design Guidelines For Switch Mode Power Supply Circuits Switched Mode Power Supply Power Supply Circuit Power Supply Design

Your Guide To Flexible Pcb Design Layout

Illustration Of The Oe Pcb Design With Main Features Noted Download Scientific Diagram

Multilayer Pcb Board Multi Layering Pcb Board Electronics Circuit

Rogers 6002 Pcb Printed Circuit Board Printed Circuit Boards Circuit Board

0 comments

Post a Comment